TECHNICAL REQUIREMENT :

● Design and Manufacture Conform to EN593

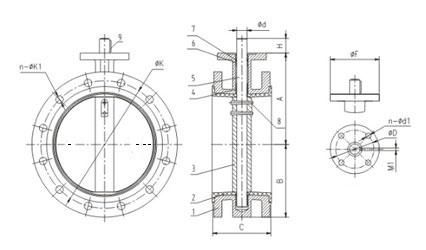

● Flange dimensions Conform to EN1092-2

● Face to Face dimensions Conform to EN558-1

● Testing Conform to EN12266-1

● Driving mode: lever, worm actuator, electric, pheumatic (The Top Flange ISO 5211 standard has also been adopted to ensure compatibility and ease of installation by providing a standardized interface between the actuator and valve. This industry-recognized specification helps to simplify the process and makes it easier for you to select the right actuator for your system.)

Double flange butterfly valve quality certification: ISO 9001:2015,ISO 14001,Pressure Equipment Directive (PED) 2015

Fire Safety Certifications for Double Flanged Butterfly Valves:API 607 and API 6FA,ISO 10497,BS 6755.

Double Flanged Butterfly Valves have been carefully designed for use in a wide range of temperatures, making them suitable for a variety of industrial applications. These valves can typically withstand temperatures from -196°C to 500°C, depending on the specific pressure conditions they encounter. Whether you are dealing with extremely cold or hot environments, these valves will maintain their integrity and operate efficiently, ensuring reliable performance in a variety of environments.

What safety integrity classes do they fulfill?

Double flanged butterfly valves typically fulfill the requirements of Safety Integrity Levels (SIL) 2 and SIL 3. These levels are part of a wider safety framework for assessing

the reliability and risk reduction capability of safety systems.

SIL 2: applies to medium-risk systems. It represents a significant reduction in the probability of failure on demand, making these valves suitable for a wide range

of industrial environments where reliable emergency shutdown functions are required.

SIL 3: This level applies to systems requiring a higher degree of risk reduction and reliability. It is typically used in environments where potential hazards

could have serious consequences. Achieving SIL 3 certification reflects the valve's superior reliability and robustness in critical applications.

Knowing the face-to-face dimensions of a butterfly valve is essential for proper installation and perfect functioning. These dimensions are the distance between the two flanges of the valve and can vary depending on the size and type of butterfly valve.

Typically, smaller butterfly valves have a face-to-face distance of about 2 inches, while larger butterfly valves can be up to 12 inches. However, keep in mind that specific sizes will vary depending on the manufacturer's production standards and specific application scenarios.

BAFAW supports a wide range of custom face-to-face butterfly valves in a variety of sizes.

Knowing the standard sizes ensures that the valve will fit accurately into the pipeline and operate smoothly. Please use this knowledge to select the appropriate valve size.