After-sales commitment

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

With years of manufacturing experience, and state-of-the-art production equipment, as well as experienced operators, Bafaw offers first-class ending solutions for your industry. Here, your purchases are the least of your worries, and we are well aware of and adept at solving your problems.

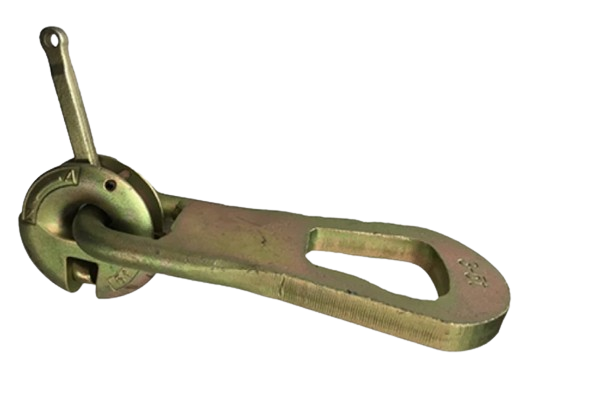

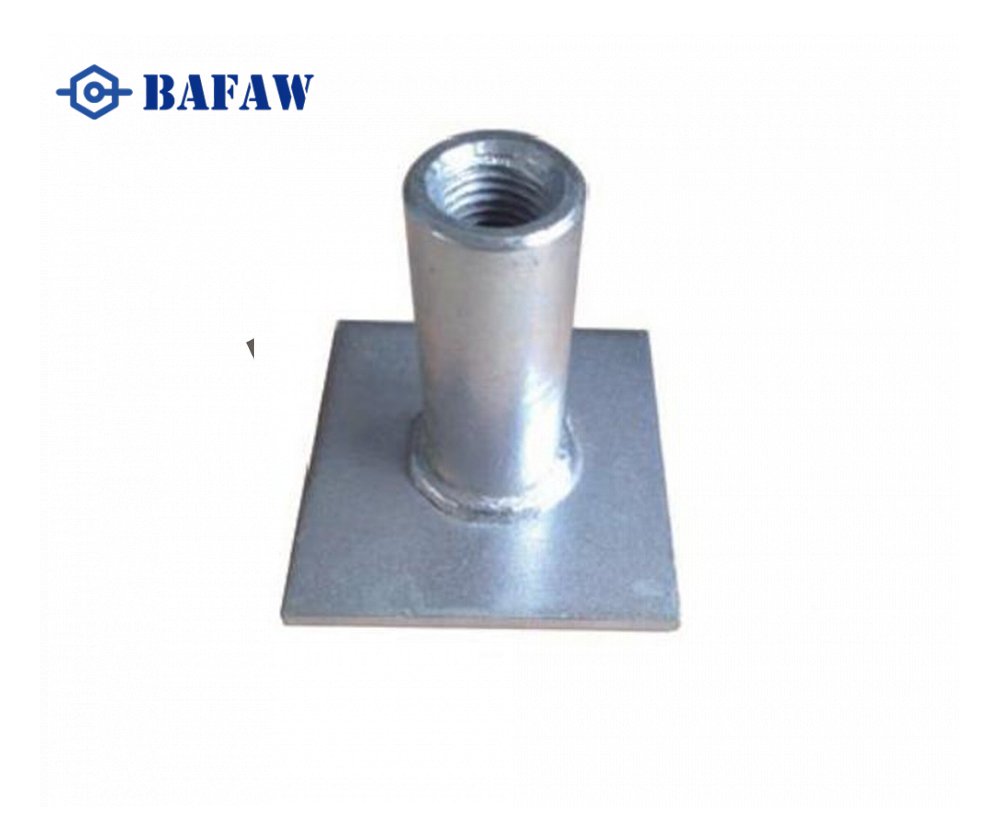

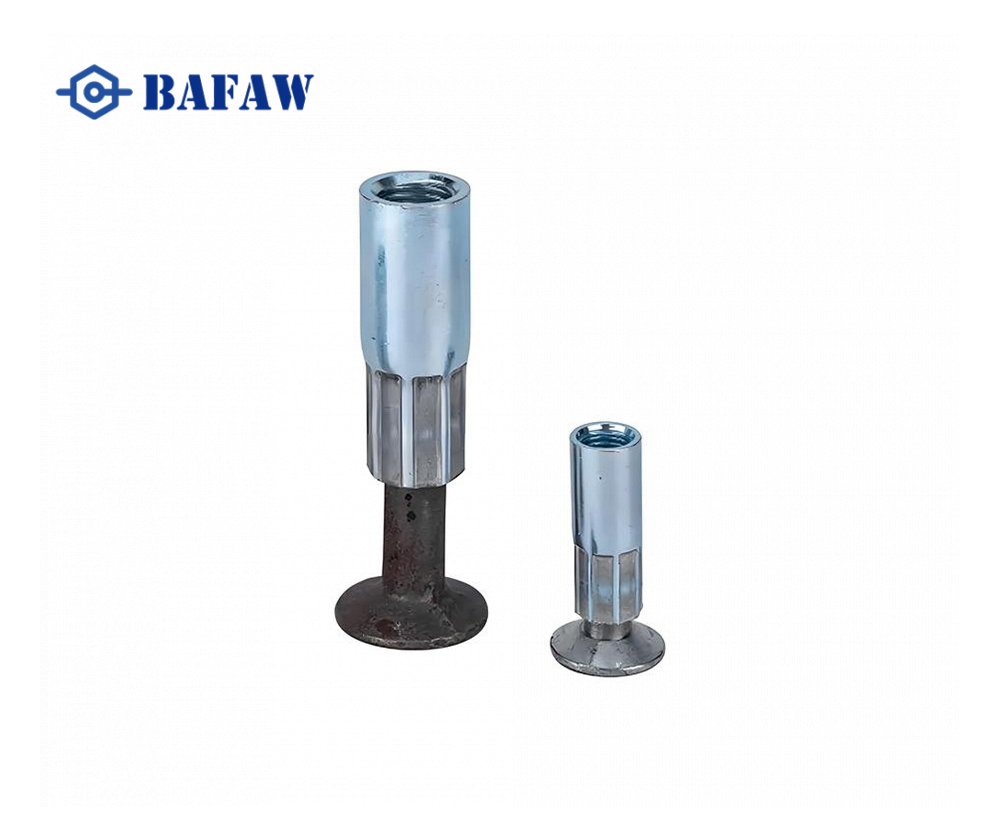

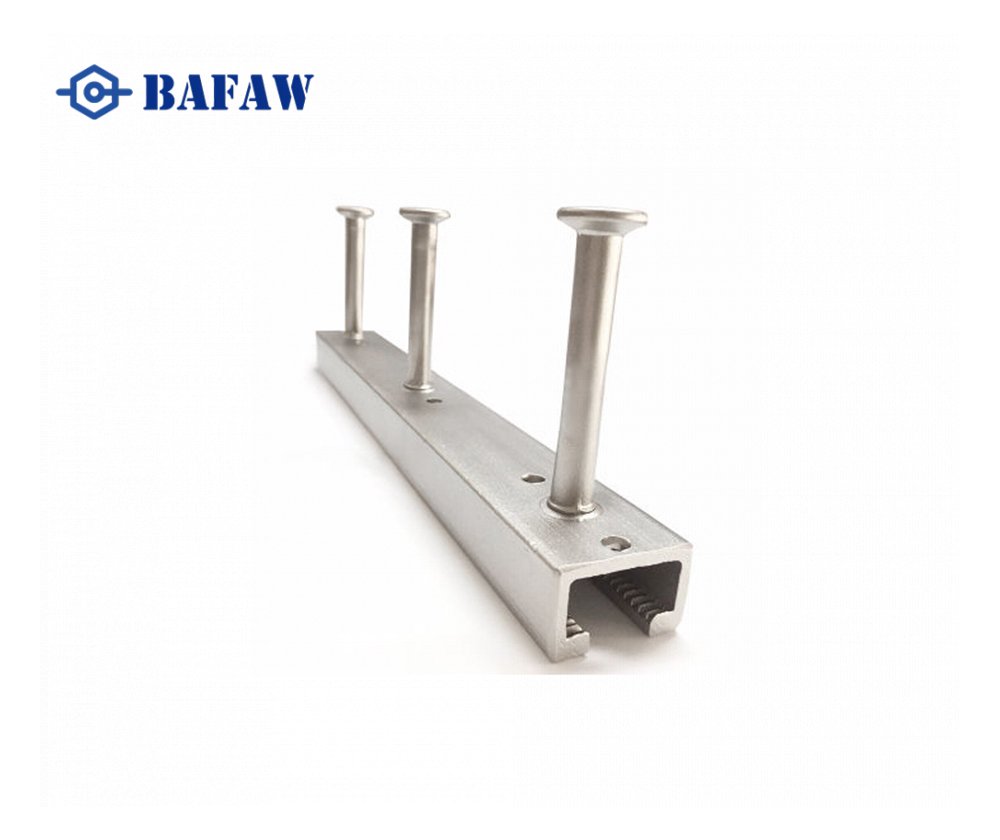

The precast lifting system is a specialized piece of equipment for the safe and efficient lifting and installation of precast concrete components. The system consists of the following main components: lifting anchors embedded in the precast elements, lifting jigs for safe gripping and securing of the elements, lifting tools such as hooks, chains and slings for connecting the lifting anchors to the lifting equipment, as well as lifting equipment such as cranes or hoists for the actual lifting and moving operations. Safety devices such as anti-slip mats and fall arrest systems are also used to ensure safety during the lifting process.

The main function of the system is to ensure that building construction is safe, efficient and precise. This greatly improves construction speed and overall construction safety . It is used in a wide variety of construction projects including bridges, tunnels, residential buildings and commercial buildings and is an important part of modern construction practice.

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

Commitment to on-time delivery ensures that the customer's production or project schedule is not disrupted.

We offer competitive pricing and guarantee price transparency to help you reduce purchasing and maintenance costs while maintaining high quality standards.

Commitment to provide high-quality products that meet or exceed industry standards to ensure product reliability and durability. Valve products with quality problems within 2 years of free replacement

Customizing a prefabricated lifting system first includes a needs analysis and design phase. The project requirements and specifications of the precast components are understood through communication with the client. Based on the needs analysis results, a suitable lifting system is designed, lifting anchors, clamps, tools, lifting equipment, and safety devices are selected and configured, and engineering calculations and verification are performed to ensure the system's feasibility.

The next step is entering the manufacturing process, drawing design and 3D drawings from the data already available, and producing specific models and specifications according to the drawings. After the first batch is produced, we send samples to the customer for confirmation. After confirmation, we will start mass production and deliver the products ahead of the specified delivery date.

Our systems have been subjected to rigorous engineering calculations and project validation, and have extensive experience of real-world use. Our systems are constructed from high-quality materials and components that minimize the risk of accidents and failures. At the same time, our systems are designed with efficiency in mind, significantly increasing construction speed, reducing site workload, and being easy to install and operate, ensuring faster and smoother lifting and installation of precast components.

In addition, we offer customized solutions, tailoring our lifting systems to the specific needs of each project to ensure a perfect match with the project requirements. We also provide comprehensive technical support and services, covering every stage of the project, from requirements analysis, design, and manufacturing to installation and commissioning. With rich experience and professional knowledge, our prefabricated lifting systems have been successfully applied in various large-scale projects, which can provide a strong guarantee for your project.