If you've ever worked with piping systems or have a keen interest in engineering, you might have come across the term "stub ends." But what exactly are they, and why are they crucial in lap joint flange connections?

What is Stub End?

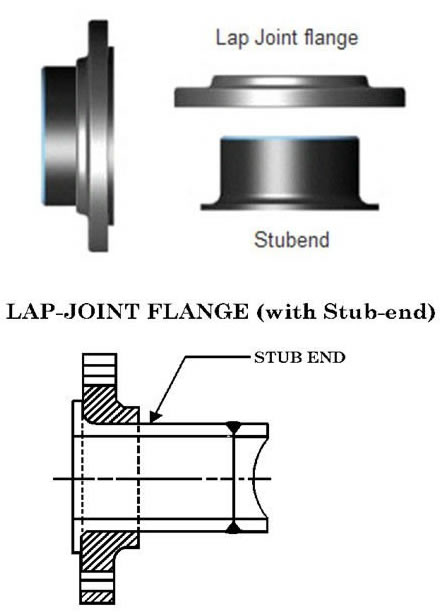

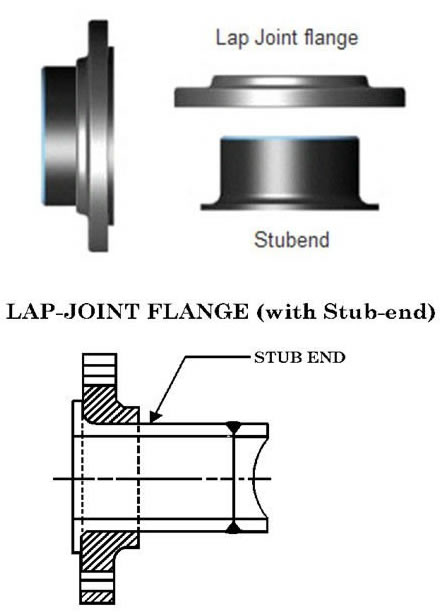

Stub ends, also known as lap joint stub ends, are short pipe sections with a flared-out end that allows them to slide into the flange. They are typically used in conjunction with lap joint flanges, where the stub end slides over the pipe and is welded to the pipe's outer surface, while the flange is free to rotate around the stub end. This design offers several advantages in piping systems, including ease of assembly, flexibility, and cost-effectiveness.

Importance in Lap Joint Flange Connections

Lap joint flange connections are widely used in industries such as oil and gas, petrochemicals, and water treatment plants due to their versatility and ease of installation. The use of stub ends in lap joint flanges plays a crucial role in ensuring the integrity and reliability of these connections.

Angular Alignment

One of the key benefits of using stub ends in lap joint flanges is the ability to achieve angular alignment between pipes. Unlike other types of flange connections that require precise alignment during assembly, lap joint flanges allow for slight misalignment between pipes. The stub end provides a rotational interface, allowing the flange to swivel around the pipe axis, thus accommodating minor alignment issues without compromising the integrity of the connection.

Flexibility

Lap joint flange connections with stub ends offer greater flexibility compared to other types of flange connections. The ability of the flange to rotate around the stub end allows for thermal expansion and contraction of the piping system without inducing stress or strain on the connection. This flexibility is especially crucial in systems where temperature variations are common, as it helps prevent premature failure due to thermal cycling.

Easy Maintenance

Another advantage of using stub ends in lap joint flanges is the ease of maintenance. Since the flange is not welded directly to the pipe, it can be easily removed for inspection, cleaning, or replacement without requiring extensive cutting or welding operations. This simplifies maintenance procedures and reduces downtime, resulting in cost savings for plant operators.

Impact on Connection Performance

The use of stub ends in lap joint flange connections has a significant impact on the performance and reliability of piping systems. By allowing for angular alignment, flexibility, and easy maintenance, stub ends help ensure leak-free connections and prolong the service life of the system. Additionally, the ability to accommodate thermal expansion and contraction reduces the risk of fatigue failure, enhancing the overall safety of the installation.

In conclusion, stub ends play a vital role in lap joint flange connections, offering numerous benefits such as angular alignment, flexibility, and easy maintenance. Their use significantly improves the performance and reliability of piping systems, making them indispensable in various industrial applications. For more information or inquiries about piping solutions and fittings, feel free to contact us.