What Is a Check Valve?

A check valve, also known as a non-return valve or one-way valve, is a mechanical device designed to allow the flow of fluid or gas in one direction while preventing backflow in the opposite direction. Picture a door that swings open when you want to go forward but stays shut if you try to gobackward. These valves are like one-way streets in plumbing. When the water or air wants to move forward, the valve opens up. But if they try to sneak back, the valve snaps shut, preventing any reverse flow.

Understanding Check Valve Configurations

Check valves, essential components in various piping systems, are designed to allow the flow of fluids in one direction while preventing backflow. Their configurations vary widely to suit different applications and pressures. Here’s a rundown of the common types of check valve configurations and how they operate:

1. Standard Check Valves

Standard check valves contain internal components, such as seals, which can be balls, flaps, or valves. The seal is pressed against the valve seat to stop reverse flow. Typically, a spring gently biases the seal into place, ensuring that the valve closes quickly when fluid flows in the reverse direction, thereby increasing the effectiveness of the valve. These configurations have a variety of components designed to create an internal seal that effectively prevents flow in the direction of the check.

2. Spring-Loaded Check Valves

In these valves, the internal flow path can take many forms. Fluid can move axially between the ball or spool and the valve body. In some designs, fluid flows through a channel inside the spool and out the center of the valve. Another design allows fluid to flow out of the inlet at a 90-degree angle. This versatility of flow paths allows spring-loaded check valves to be adapted to different system requirements.Spring-loaded check valves effectively control fluid flow through the careful design of key components such as seals, seats and light springs, allowing unidirectional fluid flow and preventing backflow.

The core sealing mechanism relies on the seal (e.g., ball bearing or valve flap) being tight against the seat, and the force exerted by the light spring pushing the seal into the seating position, ensuring that the seal remains closed when fluid attempts to flow in the opposite direction. In this way, when unwanted pressure is applied to the valve, the spring tension holds the seal tight against the seat, creating an airtight closure that effectively prevents any backflow of fluid.

3. Flexible Material Check Valiles

Ideal for low-pressure conditions, these valves use flexible materials to manage flow. The materials act either as simple diaphragms or in more complex shapes like a duckbill. These configurations respond directly to changes in pressure, opening or blocking the flow as needed.

In low-pressure applications, a check valve may utilize a flexible material that is both resilient and adaptable. This design allows the valve to maintain control based on varying pressure conditions. The material often resembles natural or synthetic rubber, which provides the elasticity needed for effective performance.

By acting as a basic diaphragm, the flexible material can easily adjust to different flow requirements. Alternatively, in a duckbill configuration, the valve mimics the shape of a duck's bill, which naturally seals under low pressure and opens as pressure increases. This innovative design ensures efficiency and reliability in low-pressure systems.

4. High-Flow Check Valves

Two common types of valves used in these applications are butterfly valves and swing check valves. These valves are designed with large flat metal gates or panels that play a key role in their operation.

The metal doors are mounted directly to the valve body and can be opened or closed automatically depending on the direction of flow. When fluid flows forward, these doors open to accommodate high flow rates.

Conversely, when fluid stops or flows in the opposite direction, the valves close to prevent backflow.

This design effectively ensures efficient and reliable operation in demanding environments. The use of butterfly and swing check valves in these applications highlights their importance in maintaining system integrity and performance.

What Types of Check Valves Are Commonly Used in High-Flow Hydraulic Applications?

In high-flow hydraulic systems, choosing the right check valve is crucial for optimal performance. Two prevalent types often used are:

Butterfly Valves: These are characterized by their circular, flat discs. The disc pivots on an axis, similar to a butterfly’s wings, allowing fluid to flow easily in one direction while preventing reverse flow when closed.

Swing Check Valves: Constructed with a hinged metal disc, these valves swing open as fluid moves through the system. Once the flow stops or reverses, gravity or backflow forces the disc to swing back into place, ensuring the line is securely shut.

Both designs are integral to preventing backflow and maintaining efficient, smooth operations in hydraulic systems.

Each check valve configuration offers unique advantages and is chosen based on specific system requirements, including flow rate, fluid type, and pressure levels. Understanding these configurations helps in selecting the right valve for a given application, ensuring efficiency

How Does a Check Valve Work?

A check valve works like a swinging door for fluids or gases, designed to allow flow in one direction while preventing any sneaky backward movement. Here's a detailed breakdown of how it operates:

Forward Flow

Imagine the check valve as a door on its hinges. When fluid or gas flows in the desired direction, it pushes the door open, allowing easy passage. It's like walking through a door that swings open in front of you. This movement is facilitated by the direct action of pressure on the valve's internal components, typical of a direct-acting device.

Automatic Opening

The check valve doesn't need any manual intervention. The force of the flowing substance naturally opens the valve, letting it move through the system with ease. It's like the door swinging open automatically when you approach. Importantly, check valves are normally in a closed position, held shut by a minimal force-producing mechanism within the valve that ensures the valve returns to a closed state when there's no pressure differential.

Backflow Prevention

Now, if the fluid or gas tries to go backward, the check valve swings into action. The door (valive) automatically swings shut, blocking any attempt at reverse flow. It's like a self-closing door that won't let you go back once you've passed through. Some check valve designs operate without a force-producing mechanism and rely solely on the pressure differential in both directions to function properly.

Pressure-Driven

The check valve operates based on pressure. When the pressure on the side where the fluid is coming from is higher than the other side, the valve opens. Conversely, if the pressure on the other side becomes higher, the valve closes to prevent backflow. It's like the valve responding to the push and pull of the fluid pressure, ensuring that the flow is controlled and directional.

By allowing fluid to flow in the desired direction and preventing backflow, check valves play a vital role in maintaining optimum pressure levels within a system. This mechanism ensures the efficient operation of pressure-sensitive equipment such as pumps, regulators and other components. In this way, check valves help to stabilize the system and prevent pressure drops or surges that could interrupt operation.

System Efficiency

Check valves ensure unidirectional flow of fluid and help maintain the required pressure conditions. This not only supports the efficient operation of various components, but also extends their service life. Equipment such as pumps and regulators rely on constant pressure to operate efficiently, and check valves are vital in providing this stability.

No External Controls

There are no buttons or levers involved – it's all about the natural forces at play. The check valve's design is simple yet effective, allowing it to work automatically without any exte

Check valves play a crucial role in reducing water hammer, a phenomenon marked by sudden pressure surges within a piping system. These pressure spikes can cause significant damage, leading to expensive repairs or total system failures.

Different Types of Check Valves and Their Applications

Check valves come in various forms, each designed for specific situations and applications:

Non-return Check Valves: These are commonly used in pump inlet and outlet ports where they allow flow in the desired direction with minimal pressure loss, while preventing any backflow.

Check valves excel in applications where one-way fluid flow needs to be maintained. By allowing fluid to flow through the system with minimal resistance, check valves ensure efficiency. Typically, one valve is installed at the pump inlet to draw fluid from the source, while the other valve is installed at the outlet to allow the pump to efficiently distribute the fluid. This setup prevents any unwanted backflow, thus safeguarding the integrity and performance of the system.

Vent Check Valves: Such valves are crucial in systems where pressure build-up could be hazardous. They open to release excess pressure but remain closed against backflow. This type is often used in automotive fuel systems to manage the pressure caused by temperature changes.

Fill and Drain Valves:

Fill and Drain Valves: These valves are used in systems that require frequent filling and draining, such as hydraulic or pneumatic systems.

They allow the system to fill with fluid and then prevent the fluid from spilling and can be opened manually to drain the system if necessary.

Typically located near the tank, fill and drain valves are critical components in maintaining system integrity. They allow fluid to enter the system,

ensuring that the fluid remains safely contained once filled. This is especially important for applications where maintaining pressure is critical.

These valves play a vital role when it comes to system maintenance or scrapping. For safety reasons, it is often necessary to depressurize a system.

In such cases, check valves can be opened mechanically or manually to allow controlled and safe discharge of system fluids.

Location: Near the tank of a hydraulic or pneumatic system.

Safety Function: Pressure reduction by manual or mechanical operation.

Function: Prevents fluid leakage and allows controlled drainage.

By understanding how these valves work, you can ensure the efficient and safe management of fluid systems in a variety of industrial applications.

Each type of check valve plays a pivotal role in ensuring the efficiency and safety of fluid and gas handling systems. Understanding the specific needs of your system is crucial in selecting the right type of check valve, ensuring it functions optimally within your infrastructure.

What is a check valve used for?

Check valvesfind applications in various industries and everyday systems due to their crucial role in maintaining the integrity and efficiency of fluid handling processes. By preventing reverse flow, they eliminate the need for additional pumps or mechanisms to counteract backflow, thereby reducing energy consumption and operational costs. Here are some common uses of check valves:

Water and Wastewater Systems

Check valves are widely used in water distribution systems to prevent backflow, ensuring that water flows in one direction and doesn't contaminate the clean water supply. This contributes to the overall efficiency of the system by maintaining water quality without requiring additional purification steps.

Oil and Gas Industry

In the oil and gas industry, check valves are employed to control the flow of fluids in pipelines, preventing reverse flow and ensuring that substances move in the intended direction. This helps reduce the need for extra pumping equipment, thus saving on energy and operational costs.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often utilize check valves to regulate the flow of refrigerants and fluids, preventing unwanted backflow and maintaining system efficiency. This eliminates the need for additional components to manage flow direction, thereby reducing energy usage.

Chemical Processing

Check valves play a crucial role in chemical processing plants, where they help control the flow of various chemicals and prevent the mixing of incompatible substances. By ensuring precise flow control, they contribute to the safe and efficient operation of the system, minimizing the risk of costly shutdowns or accidents.

Pumps and Compressors

Check valves are typically installed on the discharge side of pumps and compressors to prevent reverse rotation or backflow, protecting equipment and ensuring efficient operation. By stopping the fluid from flowing back, check valves to prevent potential damage such as pump damage, pipe collapse and water hammer.

Power Generation

Power plants use check valves in steam and cooling water systems to control the direction of flow and prevent damage to equipment caused by backflow. Check valves act as a barrier, stopping reverse flow that can lead to issues such as pump damage and contamination of sensitive components. By maintaining a unidirectional flow, they ensure the reliability and longevity of critical power generation equipment.

Fire Protection Systems

Check valves are essential in fire protection systems to ensure that water flows in one direction, particularly in sprinkler systems and fire hydrants. This guarantees the immediate availability of water during emergencies, enhancing the overall efficiency and reliability of fire protection measures.

Automotive Industry

In vehicles, check valves are used in various systems, such as braking systems and emission control systems, to control the flow of fluids and gases. This ensures the smooth operation of these critical systems, reducing the need for frequent maintenance and improving fuel efficiency.

Marine Applications

Check valves are employed in marine systems to control the flow of water, fuel, and other fluids, preventing backflow that could compromise the operation of the vessel. This enhances the efficiency and safety of marine operations by maintaining proper fluid flow.

Agriculture

Agricultural irrigation systems often utilize check valves to control the flow of water and prevent backflow, ensuring efficient water distribution. This helps in conserving water and reducing the energy required for pumping.

Food and Beverage Processing

In the food and beverage industry, check valves help control the flow of liquids during processing, preventing contamination and ensuring product quality. This contributes to efficient production processes and reduces the risk of costly recalls.

Mining and Construction

Check valves are used in mining and construction equipment to control the flow of hydraulic fluids, preventing backflow and ensuring the proper operation of hydraulic systems. This enhances the efficiency and reliability of machinery, reducing downtime and maintenance costs.

Types of Check Valves:

To support these applications, various types of check valves are utilized, each designed for specific operational needs:

Lift check valves:

Lift check valves are essential components in various fluid systems, designed to ensure unidirectional flow and prevent backflow. These valves operate using a piston or ball mechanism.

How They Work

Flow Direction: When fluid moves in the intended direction, the piston or ball is lifted off the seat, allowing the fluid to pass through easily.

Backflow Prevention: If the fluid attempts to flow in the opposite direction, the piston or ball is forced back onto the seat, effectively blocking the reverse flow.

Applications

Lift check valves are commonly used in industries where maintaining unidirectional flow is crucial, such as:

Water Treatment Plants

Chemical Processing Facilities

Oil and Gas Pipelines

Benefits

Reliability: Their simple design makes them highly reliable.

Durable: Constructed from robust materials that can withstand harsh conditions.

Each kind of check valve is essential for ensuring fluid flows correctly in systems, protecting equipment and processes across various industries.

Tilting disc check valves:

Tilting disc check valves are specialized components used in piping systems to control the flow of liquids and gases. They function by utilizing a disc that tilts within the valve body, allowing fluids to move in a single direction.

Flow Regulation: The tilting disc opens to permit fluid flow and automatically closes to prevent reverse flow.

Backflow Prevention: When the fluid attempts to flow backward, the disc tilts to seal off the passage, stopping any reverse movement.

Benefits:

Efficiency: These valves offer low resistance to fluid flow, enhancing overall system efficiency.

Quick Response: The tilting disc quickly reacts to changes in flow direction, providing immediate backflow control.

Inline check valves (Globe-Style Sliding Disc Check Valve):

Inline check valves, specifically the globe-style sliding disc check valves, are crucial in piping systems. They ensure fluid flows in a single direction, thus preventing any backflow that could cause system disruptions or damage.

Internal Mechanism: These valves use a spring-loaded disc within the valve body. When fluid flows in the desired direction, the pressure causes the disc to slide open, allowing seamless passage.

Preventing Backflow: During reverse flow, the spring mechanism forces the disc to close, effectively blocking any unwanted backflow and protecting the pipeline's integrity.

Advantages

Reliable Performance: The robust design ensures consistent operation even under variable pressure conditions.

Minimal Maintenance: The simplicity of moving parts minimizes the need for frequent maintenance.

Versatility: Suitable for various fluids, making them ideal for industries like water treatment, petrochemicals, and more.

Ball check valves:

Ball check valves are essential components in fluid systems, designed to manage flow and prevent backflow. These valves operate using a simple mechanism where a ball rests on a seat within the valve body. As fluid flows in the intended direction, the pressure lifts the ball off the seat, allowing fluid to pass through.

When the fluid attempts to flow backward, the ball is pushed back against the seat, creating a seal that prevents reverse flow. This automatic operation ensures one-way flow, making ball check valves ideal for various applications.

Direction Control: They allow fluid to flow freely in one direction while blocking any reverse flow.

Self-Activating: No manual intervention is needed; the valve functions solely based on the fluid pressure.

Versatility: Suitable for use in both liquid and gas systems, offering wide-ranging industrial applications.

By incorporating ball check valves into your fluid systems, you can ensure efficient and reliable one-way flow, protecting your equipment from potential damage caused by backflow.

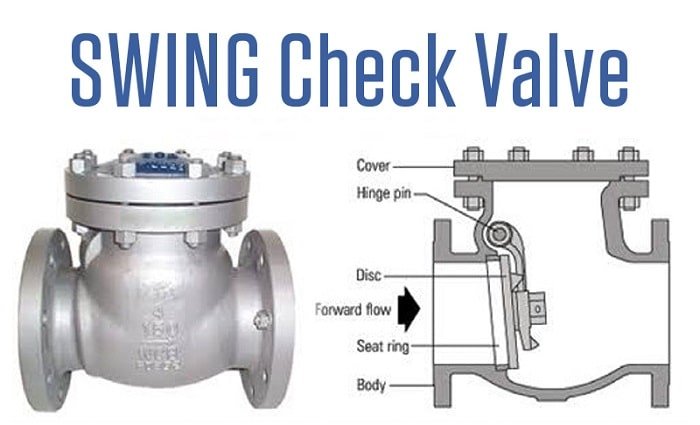

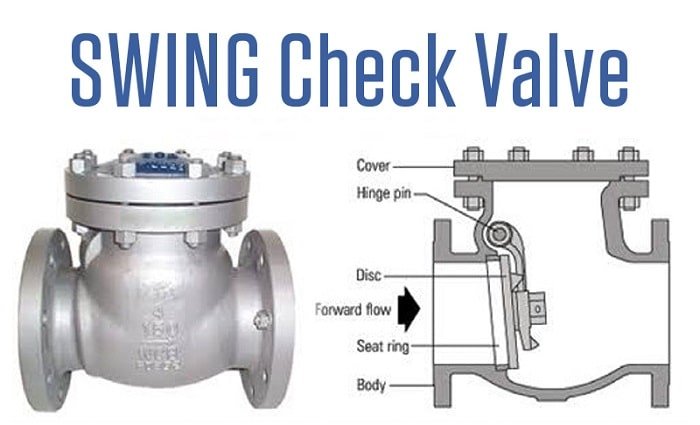

Swing check valves (Butterfly Check Valve):

Swing check valves, often referred to as butterfly check valves, are crucial components in piping systems that ensure a unidirectional fluid flow. They operate through a movable disc that swings open to allow fluid to pass through when it flows in the intended direction.

Swinging Disc Mechanism: The disc swings open when fluid moves forward, permitting flow.

Backflow Prevention: If fluid reverses direction, the disc swings shut to block any backward flow, thereby preventing potential damage or contamination.

Ideal for systems requiring reliable backflow prevention, swing check valves are widely used in various industries, including water treatment, oil and gas, and chemical processing.

Wafer check valves:

Wafer check valves are a specific type of valve designed to manage the flow of fluids in one direction and prevent backflow. They are typically installed between flanges, making them a compact and efficient option for various piping systems.

Spring-Loaded Disc: These valves use a spring-loaded disc mechanism to control the flow of fluid. The disc opens to allow fluid to pass through in one direction.

Backflow Prevention: When the fluid attempts to flow in the opposite direction, the spring mechanism closes the disc, effectively preventing any backflow.

Benefits:

Space-Saving Design: Their wafer-thin construction makes them ideal for systems where space is limited.

Efficient Flow Control: The spring-loaded disc ensures precise and effective regulation of fluid movement.

Easy Installation: Being mounted between flanges simplifies the installation process, saving both time and labor.

Applications:

Industrial Use: Common in chemical, petrochemical, and water treatment industries.

HVAC Systems: Often used in heating, ventilation, and air conditioning systems to maintain proper flow.