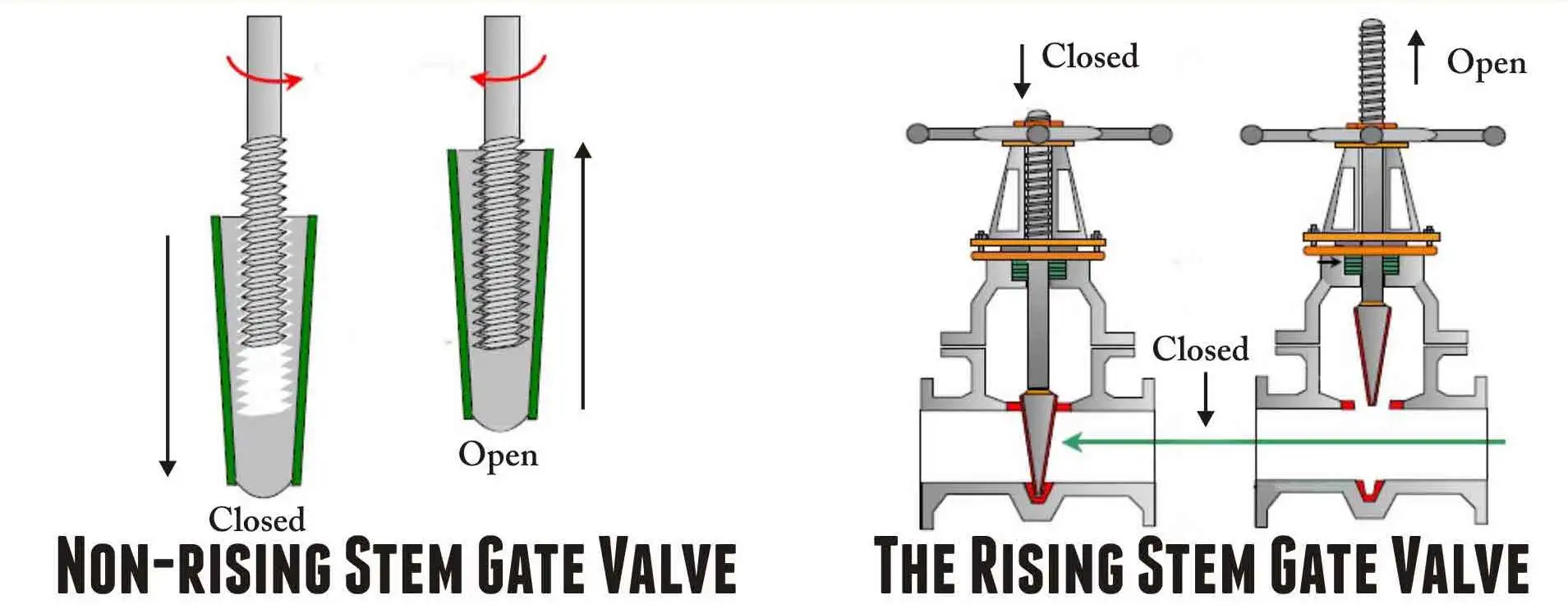

The Non-Rising Stem Gate Valve is a common type of gate valve. It is different from the Rising Stem Gate Valve. In this valve, the stem does not rise when opening or closing. Instead, it is fixed to the valve body and only rotates or moves in a straight line.

People often use this valve in tight spaces. It is also used where the valve stem should not be exposed. Additionally, this valve suits applications where users fix its position.

BS5163 Resilient Seated Non-Rising Stem

Key Features of the Non-Rising Stem Gate Valves

Stem Fixed: The stem of a non-rising stem gate valve does not rise or fall during the opening and closing of the valve. The stem is usually fixed inside the valve. It controls the gate's opening and closing by rotating or moving back and forth.

Space saving: The valve stem stays down, making it great for places with limited installation space. Especially in underground, inside walls or in areas with dense equipment, non-rising stem gate valves can save a lot of space.

Suitable for deeply buried pipelines: Non-rising stem gate valves are great for underground installations. They do not require the valve stem to be exposed.

Pollution prevention: The valve stem is not exposed. This helps keep outside contaminants from entering the valve and improves sealing.

Easy maintenance: Although it has a fixed stem, the overall structure is simple and easy to operate and maintain. For long-term use of the equipment, maintenance is more convenient.

Good sealing: Non-rising stem gate valves have strong sealing performance. They are great for fully opening and closing fluids. The valve plate is in close contact with the valve seat during closing to prevent leakage.

Scope of application: It is commonly used in industrial pipelines. This is especially true for cases where the valve does not need to open or close often, or stays closed for a long time.

High stability: This type of gate valve is very durable. It works well in places that need long-lasting use and rare operation

The Non-Rising Stem Gate Valve is often used in tight spaces or where stable operation is needed for a long time.

For example, in underground piping systems or small areas, these valves save space. They also prevent the hassle of rising stems. In these cases, the stem-retained design is great for places where the valve needs protection from the weather. It also helps prevent stem wear and pollution .Maintaining and adjusting the non-rising stem gate valve is easy.

However, it is important to check it regularly. The sealing part can age and wear out over time, so it needs inspection and replacement. This is especially important when used in high temperature and high pressure environments.