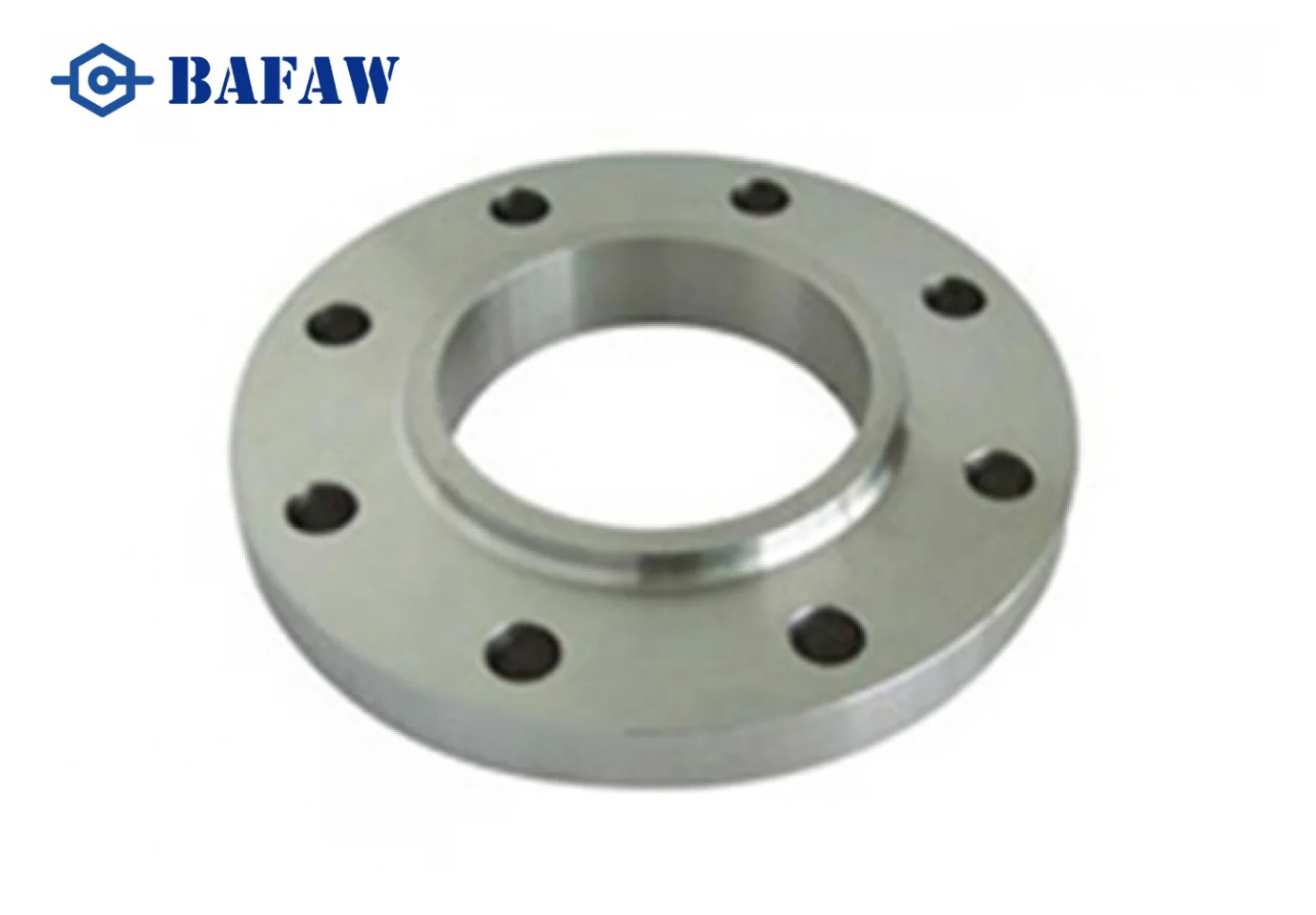

In industrial piping systems, every component plays a crucial role in ensuring seamless operations and minimizing maintenance costs. Among these components, lap joint flanges stand out as a cost-effective solution that can significantly reduce maintenance expenses over time. By understanding the benefits of lap joint flanges, you can make informed decisions to optimize their piping systems while enhancing cost efficiency.

Reduced Downtime

One of the primary advantages of lap joint flanges is their ability to minimize downtime during maintenance activities. Unlike welded flanges, which require time-consuming and labor-intensive procedures for detachment and reattachment, lap joint flanges offer a simpler and quicker disassembly process. This ease of disconnection allows maintenance teams to swiftly access and service the pipeline without extensive downtime, resulting in minimal disruption to production schedules.

Fewer Maintenance Interventions

The design of lap joint flanges contributes to fewer maintenance interventions over the lifespan of the piping system. Their unique configuration enables easy inspection and replacement of components without necessitating comprehensive overhauls. As a result, maintenance tasks such as inspection, cleaning, and repairs can be performed efficiently, reducing the frequency of interventions and associated costs.

Extended Equipment Lifespan

Lap joint flanges promote the longevity of industrial piping systems by minimizing stress and wear on interconnected components. Their flexible design accommodates thermal expansion and contraction, which helps mitigate the risk of fatigue failure and premature deterioration. By reducing the strain on pipelines and equipment, lap joint flanges contribute to an extended lifespan for critical assets, thereby lowering replacement and repair expenses in the long run.

Cost Efficiency

In addition to their operational benefits, lap joint flanges offer cost efficiency through reduced material and labor expenditures. Unlike welded flanges that require specialized welding equipment and skilled labor for installation, lap joint flanges can be assembled using standard tools and techniques, reducing installation time and associated expenses. Furthermore, their modular design simplifies modifications and upgrades, allowing companies to adapt their piping systems to changing requirements without significant cost implications.

Lap joint flanges present a compelling solution for lowering maintenance expenses in industrial piping systems. By facilitating quick disassembly, minimizing maintenance interventions, and promoting equipment longevity, lap joint flanges offer tangible cost-saving benefits for companies across various industries.