Understanding Hex Head Plugs and Their Construction

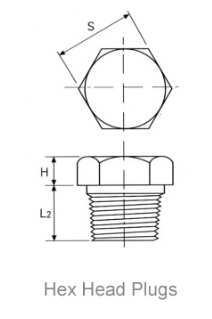

Hex head plugs are an essential type of pipe fitting used to close off the end of a threaded pipe. Designed with a hexagonal head, these plugs allow for easy installation and removal using a wrench.

Material and Standards

Hex head plugs are commonly made from forged carbon steel. This material is known for its durability and ability to withstand high pressures. Such plugs are particularly suitable for various industrial applications due to their robustness.

Certification and Standards: These plugs are manufactured, tested, and certified to meet specific standards such as ASME 3A-105N & ASTM A105N, which ensure the quality and safety of the fittings.

Threading: The threads of these plugs conform to the ASME B1.20.1 standard, which specifies the dimensional requirements for tapered pipe threads for general use.

Variants and Availability

Hex head plugs come in different sizes to accommodate various pipe diameters, ranging from small to large dimensions. Each size corresponds to the National Pipe Thread (NPT) standard, ensuring compatibility with similarly threaded pipes.

Additional Compliance and Features

Socket Weld Inserts and Unions: In addition to hex head plugs, complementary fittings such as socket weld inserts and unions are available. These conform to MSS-SP-79 and MSS-SP-83 standards, respectively, adding versatility to your piping systems.

Outlet Fittings: Forged carbon steel outlet fittings that conform to MSS-SP-97 are also produced, enhancing the options available for diverse installations.

Quality Assurance

ISO Certification: The manufacturing facilities for these components often boast ISO 9001:2008 certification, ensuring a consistent level of quality across products.

Options for Canadian Registration Numbers (CRN): If you're operating in Canada, these plugs can be registered for compliance, available upon request.

Whether you're sealing off a pipe end or preparing for future expansions, hex head plugs crafted from forged carbon steel offer reliable performance in demanding environments.

| Size: | 1/8"-4"(6mm-100mm) |

| Specification: | Dim. Spec: ANSI B16.11 , MSS SP-79 |

| Material Spec: | ASTM A105 , Stainless Steel304, SS304L, SS316, SS316L |

| Size of raw material: | DIA. 19-85MM Round Bar |

| Type: | Elbow, Cross, Street Elbow, Tee, Boss, Coupling, Half Coupling, Cap,Plug, Bushing, Union, Swage Nipple, Bull Plug, Reduced Insert, Pipe Nipple etc. |

| Connection Type: | Socket-Weld and Threaded (NPT, BSP) |

| Rating: | 2000LBS, 3000LBS, 6000LBS, 9000LBS. |

| Marking: | 1.Carbon and alloy steel: marked by stamping. |

| 2.Stainless:Marked by electro-etched or jet printed or stamped |

| 3.3/8" under: brand only |

| 4.1/2" to 4": marked brand. material. heat no. b16 (blong to ANSI B16. 11 product),pressure and size. |

| Paking: | Carton/ Plywood cases |