Pressure Testing (API 6D Annex F):

Fire Safety (API 6FA):

Cryogenic Validation (BS 6364):

Sour Service (NACE MR0175/ISO 15156):

Certification Tip: Always request mill test reports (MTRs) with actual chemistry – we once found a “NACE-compliant” valve with 0.35% carbon content (limit 0.23%).

Industry-Specific Applications

Offshore Oil & Gas

Petrochemicals

Ethylene cracker transfer lines (1,200°C thermal sleeves required)

Hydrogen service (embrittlement-resistant F91 body materials)

LNG Terminals

Power Generation

Selection Criteria: Beyond the Data Sheet

Cycle Life Validation:

Erosion Analysis:

Thermal Management:

Coefficient of expansion matching (e.g., Invar spacers for LNG valves)

Steam tracing requirements for waxy crude

Actuation Compatibility:

For sour gas, specify non-rotating stems to prevent galling

Seat Material Selection: The Hidden Decider

| Application | Best Materials | Failure Mode Avoided |

| Dry Gas | RPTFE + MoS2 filler | Cold flow deformation |

| Crude Oil | 316L + Stellite 6 overlay | Erosion-corrosion |

| Caustic Fluids | PEEK + 40% carbon fiber | Chemical swelling |

| High-Pressure Hydrogen | Graphoil + Inconel 718 | Hydrogen embrittlement |

| Slurry Service | Tungsten carbide vs. SiC | Particle embedment |

FAQ: Field-Proven Answers

Can DBB valves replace double valve + bleed configurations in all services?

A: Only for ANSI/ASME B31.3 Category D fluids. For Category M (toxic/flammable), use double valves with independent supports.

How to verify DBB functionality without process shutdown?

A: Implement acoustic emission monitoring – detected 0.08 mm seat wear in a Saudi Aramco gas plant.

Best practices for DBB maintenance?

Quarterly torque trend analysis (10% increase triggers inspection)

Annual cavity pressure decay test (max 1 bar/hr drop)

5-year seat removal/rebuild (critical for elastomeric seats)

How to handle thermal expansion in high ΔT applications?

ExxonMobil’s Sakhalin project used coefficient-matched body/bolt materials (WC9 body with 8630 bolts) to prevent flange leaks at -50°C.

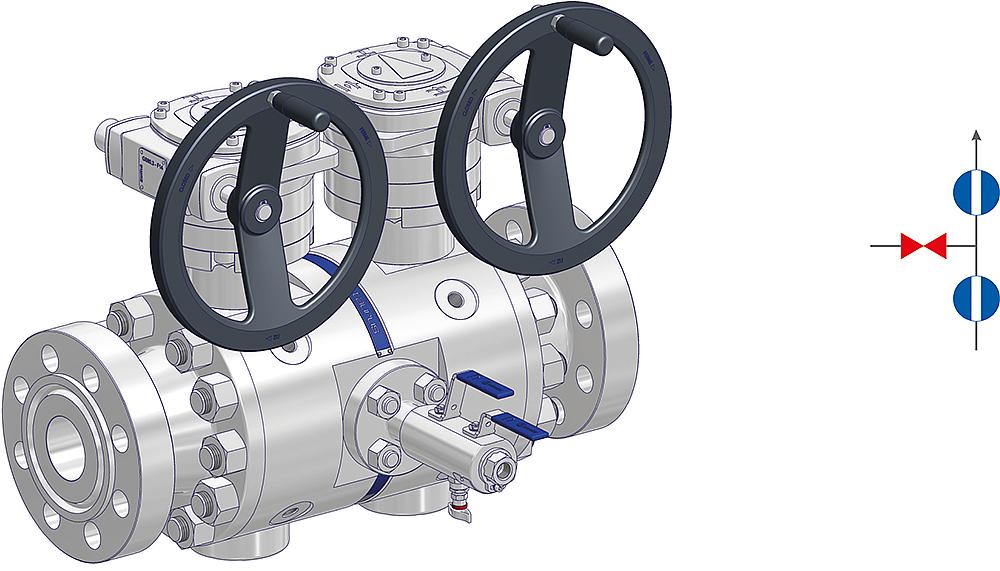

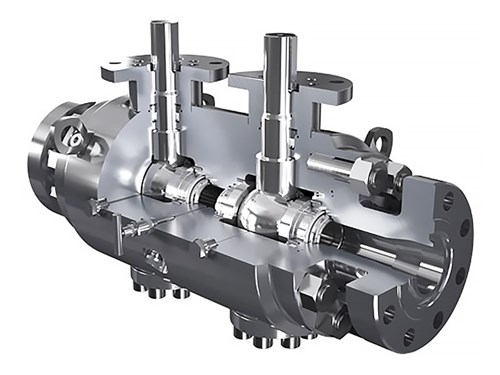

What is the difference between DBB Valve and Double Isolation Valve?

A DBB valve provides two independent seals with a bleed valve, while a double isolation valve offers two separate isolation valves without a bleed mechanism.

How do you identify a Double Block and Bleed Valve?

A double block and bleed valve typically features two isolation valves and a small bleed or drain valve positioned between them.

Why are DBB valves used in pipelines?

DBB valves are used in pipelines to ensure complete isolation during maintenance or product transfer, preventing cross-contamination and ensuring safety.

Double Block and Bleed Valves are vital components in critical applications where safety, reliability, and zero leakage are paramount. From pipelines to instrumentation systems, DBB valves provide a robust isolation solution while meeting stringent industry standards.

Understanding the various types, working principles, and selection factors of DBB valves will help engineers and procurement teams make informed decisions when specifying valves for their systems.