Materials and Manufacturing Processes of Half Couplings - Impact on Performance and Durability

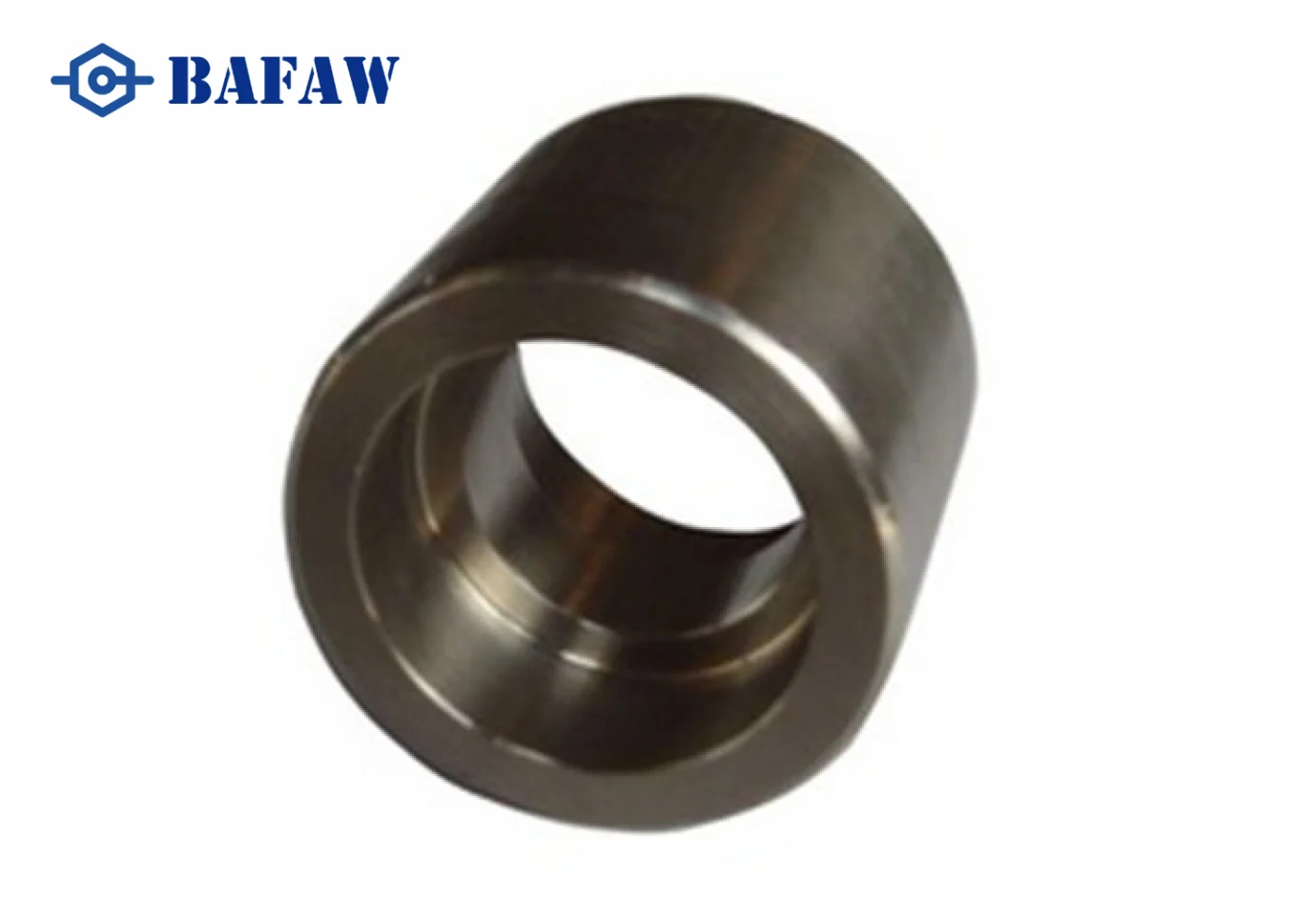

March 31, 2024Have you ever wondered about the materials and manufacturing processes that contribute to the performance and durability of half couplings? These essential components play a significant role in connecting pipelines securely and efficiently. We'll explore the different materials commonly used for half couplings, such as stainless steel, copper, cast iron, and how their manufacturing processes influence their performance and durability.

Materials Used in Half Couplings

Stainless Steel

Stainless steel is a popular choice for half couplings due to its excellent corrosion resistance, strength, and durability. It is suitable for a wide range of applications, including those involving high temperatures, corrosive fluids, and harsh environments. Stainless steel half couplings are typically manufactured using casting or machining processes, resulting in precise dimensions and smooth surfaces.

Copper

Copper half couplings offer good conductivity, corrosion resistance, and antimicrobial properties, making them suitable for plumbing and HVAC applications. They are often used in potable water systems and air conditioning units. Copper half couplings can be manufactured through casting or forging processes, with machining used for finishing touches and thread creation.

Cast Iron

Cast iron half couplings are valued for their strength, durability, and heat resistance. They are commonly used in industrial applications, such as steam piping, where robustness is essential. Cast iron half couplings are typically produced through casting processes, where molten iron is poured into molds and allowed to cool and solidify. This results in a strong and durable product with precise dimensions.

Brass

Brass half couplings offer a combination of strength, corrosion resistance, and aesthetic appeal. They are often used in decorative plumbing fixtures and fittings, as well as in applications requiring a durable and visually pleasing material. Brass half couplings are typically manufactured through casting or machining processes, with polishing and plating used for finishing touches.

Impact of Manufacturing Processes

Casting: Casting is a common manufacturing process for half couplings, especially those made from metals like cast iron, brass, and aluminum. It involves pouring molten metal into a mold cavity, allowing it to solidify, and then removing the casting from the mold. Casting processes can produce complex shapes and intricate details, making them ideal for half couplings with specific designs or features.

Machining: Machining processes, such as turning, milling, and drilling, are used to create precise dimensions and smooth surfaces on half couplings. This is particularly important for threaded connections, where accuracy is essential for achieving a tight seal. Machining also allows for customization and fine-tuning of half couplings to meet specific requirements.

Forging: Forging involves shaping metal by applying compressive forces, typically with a hammer or press. It is often used to create half couplings from materials like copper, brass, and steel. Forging processes result in parts with improved strength and toughness compared to cast or machined components. This makes forged half couplings suitable for applications requiring high mechanical properties and resistance to fatigue.

Whether made from stainless steel, copper, cast iron, or brass, half couplings are essential components of pipeline systems, providing secure connections and ensuring efficient operation. For expert assistance with your pipeline system needs and to explore our range of high-quality half couplings and fittings, pls feel free to contact us.